News detail

Installation method of amorphous refractory lining for ladle

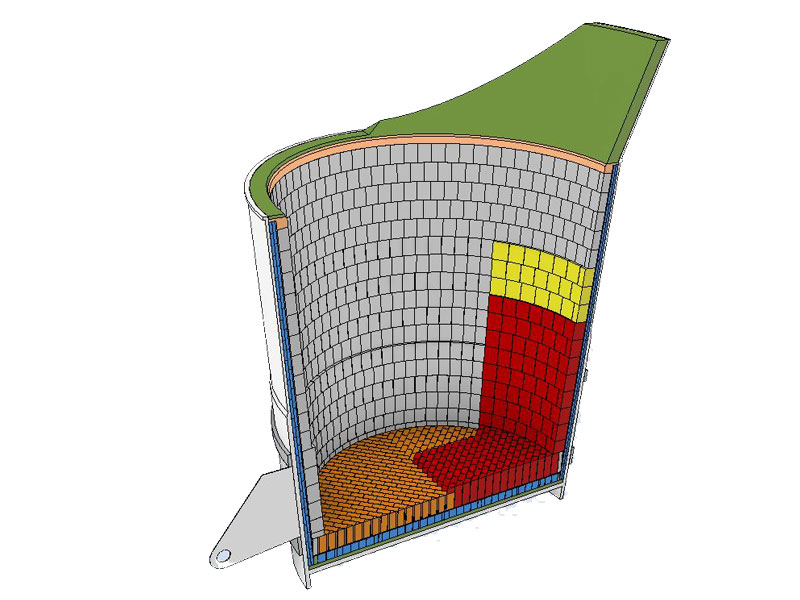

In the steel smelting industry, ladle is an important container for carrying high-temperature molten steel. The quality and installation method of its lining are directly related to the quality of molten steel, production efficiency and production safety. As a new type of refractory material, amorphous refractory lining is gradually widely used in the construction of ladle lining due to its advantages such as convenient construction and strong adaptability. This article will introduce in detail the installation method of amorphous refractory lining for ladle.

1. Preparation before construction

Before construction, the required materials and tools must be prepared first. Materials include amorphous refractory materials, refractory castables, refractory fiberboards, etc.; tools include stirrers, vibrators, templates, steel rulers, spirit levels, etc. At the same time, the steel structure of the ladle must be fully inspected to ensure the integrity and stability of the steel structure.

2. Treatment of the bottom of the ladle

The treatment of the bottom of the ladle is one of the key steps in the installation of the lining. First, it is necessary to clean the oil, rust and other impurities on the bottom of the ladle to ensure that the bottom surface is clean and flat. Then, according to the shape and size of the bottom of the ladle, install the bottom template and use refractory fiberboard for insulation. Next, lay a layer of refractory castable on the bottom template as the bottom layer of the lining.

3. Mixing and pouring of amorphous refractory materials

The mixing and pouring of amorphous refractory materials are the core steps of lining installation. First, mix the amorphous refractory materials with water in a certain proportion and stir evenly until a suitable viscosity is reached. Then, pour the mixed refractory materials into the ladle and vibrate them with a vibrator to make the refractory materials fully dense and free of bubbles. During the pouring process, pay attention to controlling the pouring speed and pouring amount to ensure the uniformity and thickness of the lining.

4. Treatment of side walls and top

After pouring the amorphous refractory materials at the bottom and side walls, the side walls and top need to be treated. First, lay a layer of refractory fiberboard on the side wall as an insulation layer. Then, lay a layer of refractory castable on the insulation layer as the side wall part of the lining. On the top, refractory fiberboard and refractory castable also need to be laid to form a complete lining structure.

5. Curing and baking

After the lining is poured, it needs to be cured and baked. Curing at room temperature for 8 to 12 hours to fully harden the lining. Then, baking treatment is carried out. By gradually increasing the baking temperature, the moisture and organic matter in the lining are volatilized to enhance the strength and fire resistance of the lining. The temperature and time must be strictly controlled during the baking process to avoid cracking, deformation and other problems in the lining.

6. Quality inspection and acceptance

After the lining is installed, quality inspection and acceptance are required. First, check the appearance of the lining to ensure that the surface of the lining is flat, without cracks, and without falling off. Then, the fire resistance test is carried out to test the fire resistance and thermal insulation performance of the lining by simulating the high temperature environment in actual production. Finally, acceptance is carried out according to the test results to ensure that the lining meets the design requirements and production requirements.

7. Use and maintenance

During use, attention should be paid to the maintenance and management of the lining. Regularly clean the slag and impurities on the surface of the lining to keep the lining clean and smooth. At the same time, the temperature and flow of the molten steel should be controlled to avoid excessive thermal shock and wear on the lining. When the lining is found to be damaged or aged, it should be repaired or replaced in time to ensure the normal use of the lining and the quality of the molten steel.

In summary, the installation method of the amorphous refractory lining for the ladle includes the preparation work before construction, the treatment of the bottom of the ladle, the mixing and pouring of the amorphous refractory, the treatment of the side wall and the top, the maintenance and baking, the quality inspection and acceptance, and the use and maintenance. By strictly controlling the quality and process requirements of each link, the quality and use effect of the lining can be ensured, providing strong guarantee for the safe and efficient production of the steel smelting industry.

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!