News detail

How to improve the riser insulation process and feeding efficiency of cast refractory products?

Riser Feeding Principle

Basic Conditions for Riser Feeding

(1) Solidification Time: The solidification time of the riser should be greater than or equal to the solidification time of the casting (the part being fed);

(2) Feeding Liquid Volume: The riser should have sufficient molten liquid to compensate for the liquid shrinkage and solidification shrinkage of the casting;

(3) Feeding Channel: During solidification, a feeding channel for liquid flow exists between the riser and the feeding part of the casting, with the expansion angle pointing towards the riser.

To achieve sequential solidification feeding, the selection of the riser location, whether the effective feeding distance of the riser is sufficient, and the reasonable use of the riser and chills are also necessary to enhance the riser feeding effect.

Riser Feeding Principle Generally

The design department has already designed the riser positions in cast refractory products. In principle, placing risers in thick-walled sections and hot spots (i.e., areas of concentrated heat with large inscribed circle diameters) of the casting is an effective measure to prevent shrinkage cavities and porosity. The riser size should ensure that the riser solidifies later than the area it feeds on, and that there is a sufficient supply of molten metal. The “sequential solidification principle” is adopted, establishing a gradually increasing temperature gradient on the product from the part furthest from the riser towards the riser, thus achieving sequential solidification from the part furthest from the riser towards the riser; that is, the part furthest from the riser solidifies first, the part closer to the riser solidifies later, and the riser itself solidifies last.

Riser Design

The dimensions of risers in cast refractory products mainly refer to their root width and height, as shown in Figure 1. If the riser size is too large, although it can meet the feeding requirements of the product, it increases the product cost; if the size is too small, shrinkage porosity and shrinkage cavities will occur in the product. Therefore, correctly determining the riser size is of great significance for improving product quality and reducing costs.

Determining the Placement and Number of Risers

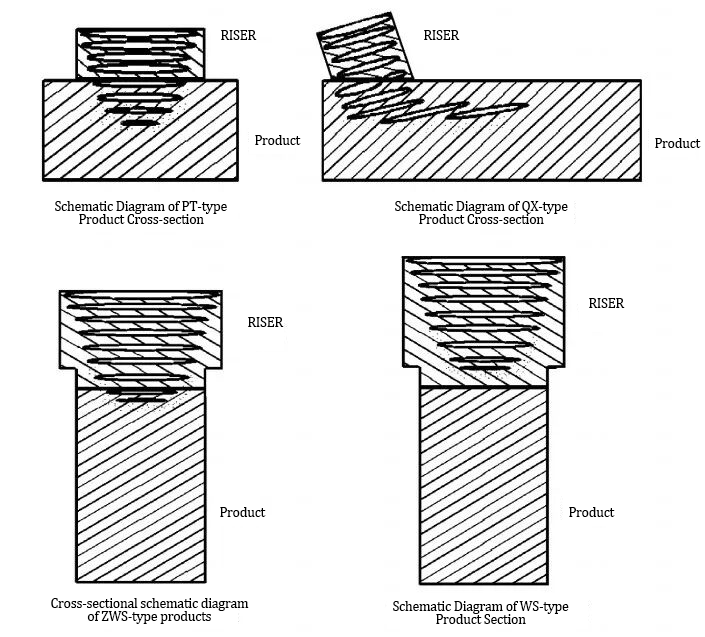

The location of risers for cast refractory materials PT, QX, and finished products has already been determined by the design unit on the drawings. The rationality of the riser location directly affects the feeding efficiency of the riser and the quality of the finished product. The basic principles to be followed when determining the riser location are:

(1) Conform to the principle of directional solidification; the riser should be placed as high as possible above the feeding location of the product or on the last solidified hot spot;

(2) Place it at the highest and thickest point of the product to utilize the gravity of the molten liquid within the riser for feeding;

(3) Place the riser on the machined surface or rough-machined surface as much as possible to reduce the amount of finishing work;

(4) Risers can be set separately according to the effective feeding distance, the size of the feeding area, and the hot spot;

(5) Risers should not be placed at stress concentration points in the product, otherwise it will increase the stress concentration tendency and cause cracks in the product.

Determining the Riser Size

For ease of operation and cost considerations, since cast refractory products are mostly cuboids or plates, their risers are often cuboids or frustums. Experience shows that the volume shrinkage rate of AZS products is mostly 12%–15%, and high-alumina products reach 30%.

For straight cast refractory products of PT, QX, and ZWS, the proportional method and the feeding liquid method are followed. Typically, based on the product’s dimensions (a×b×c), plus machining allowance and the product’s shrinkage rate, a graph is drawn, and the length (a+m), width (b+m), and height (h) dimensions of the square riser are directly measured and calculated; m is a constant.

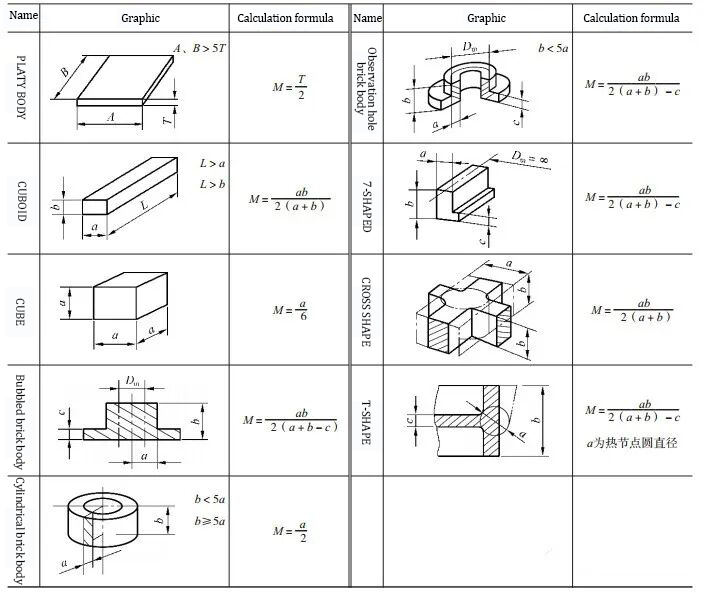

For irregularly shaped cast refractory products of PT, QX, and ZWS, the shape is considered. Referring to the casting modulus method in the casting industry, simple geometric shapes and modulus calculations are shown in Table 1. The casting modulus and riser modulus are calculated, and then the specific dimensions of the required riser are found in the relevant standard riser table.

Ways to Improve Riser Feeding Efficiency

Since risers in cast refractory products are open-top risers, connected to atmospheric pressure, the main ways to improve riser feeding efficiency, given the short solidification time of molten refractory materials, are to use natural pressure risers, heat-generating and heat-insulating risers, and various process measures to control the solidification of the molten metal within the riser.

Appropriately Increasing the Riser Height to Increase Feeding Pressure of the Molten Metal

This is achieved using natural pressure risers and the operation of tamping the riser with a steel rod. After pouring, a crust forms on the riser surface, and the external atmospheric pressure acts on the surface of the molten metal inside the riser, forming a feeding pressure resulting from the combined effect of atmospheric pressure and the weight of the riser’s liquid column, thus enhancing the feeding effect. After the mold riser is filled, the surface of the molten metal is tamped up and down with a steel rod to prevent premature solidification and crust formation on the top surface of the riser, allowing atmospheric pressure to act on the molten metal surface of the riser for a longer period, increasing the feeding effect of the atmospheric pressure riser.

Using exothermic risers to prolong riser solidification time

Methods to prolong riser solidification time include: applying insulating or exothermic agents to the riser, using exothermic risers, insulating risers, and arc-heated risers.

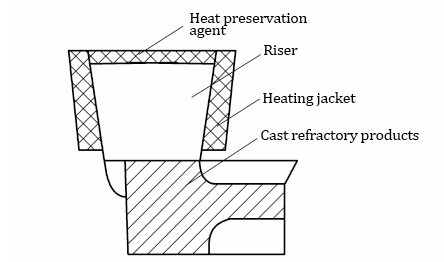

Ordinary risers solidify relatively quickly, and the melt that solidifies early in the riser does not provide feeding. To improve the feeding conditions and efficiency of the riser, exothermic risers can be used. An exothermic riser is a riser covered with an exothermic agent, or a riser with a sleeve made of exothermic and insulating materials installed on the mold, whose inner wall has the same shape as the riser portion. Due to the exothermic reaction of the exothermic material, the solidification rate of the riser is slowed down, thereby significantly improving the utilization rate of the melt within the riser.

The root of the heating riser sleeve has a 10-40mm ordinary sand ring to prevent the heating riser sleeve from directly contacting the molten metal and causing defects such as sand adhesion and carbon enrichment. When using a heating riser, after the mold is filled, a heating and insulating agent should be sprinkled on the top surface of the riser to prevent the riser from dissipating heat too quickly. The heating riser sleeve is composed of heating agent, insulating agent, and binder.

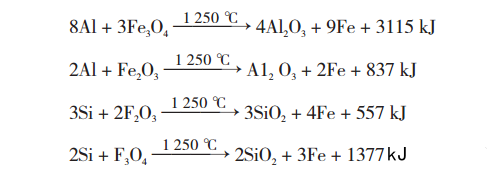

(1) Heating agent is a mixture that can release heat when it undergoes a chemical reaction under certain temperature conditions. The heating agent used in heating riser sleeves is generally composed of materials such as aluminum powder, ferrosilicon powder, and iron oxide powder. The mixture of aluminum powder and iron oxide powder is called thermite. Under the thermal action of the molten metal, when the temperature of the heating agent is 1250℃, aluminum and silicon are violently oxidized and release a large amount of heat. The chemical reaction is as follows:

The temperature of the reaction products can reach over 3000℃. The molten liquid in the riser is intensely heated and then slowly cooled, prolonging the solidification time of the molten liquid in the riser and greatly improving the feeding efficiency. Thermite has a high calorific value, reacts rapidly, and has a short action time; ferrosilicon powder has less calorific value and acts slowly, which is beneficial for prolonging the action time. The exothermic agent needs to be heated to over 1250℃ to react, which is very easy to achieve for risers of cast refractory products.

(2) Insulating Agent Commonly used insulating materials for cast refractory products include expanded perlite, vermiculite, macroporous ceramsite, lightweight insulating bricks, and high-temperature used, crushed waste molding sand (quartz). Economic indicators show that using high-temperature used, crushed waste molding sand and lightweight insulating bricks is relatively economical and feasible. Its function is to prolong the exothermic time of the exothermic agent and to maintain heat. (3) Commonly used binders include water glass, bentonite, bauxite cement, and phenolic resin. Heating risers have higher feeding efficiency than ordinary risers, with a product qualification rate of 85%–90%. They are simple to operate, easy to control, safe, and reliable, and can be widely used in the production of large-scale QX, ZWS, and WS cast refractory products. Other heating risers include electrothermal feeding risers. One graphite electrode is placed at the bottom of the riser, and another adjustable-height electrode passes through the refractory protective cover and is suspended at the top of the riser. An arc is ignited between the molten surface and the graphite electrode inside the riser to keep the riser in a molten state, ensuring sufficient feeding of the cast refractory product.

Implementing secondary casting to increase riser thermal energy

After the natural pressure riser is cast, a crust forms on the riser surface. The molten surface is then stirred up and down with a steel rod, repeated multiple times. After a certain period, the riser is finally finished, and then molten material is poured in again. This greatly improves the feeding effect of the riser. Secondary pouring is not merely about adding molten metal, but rather about increasing the riser’s thermal energy; therefore, its function is similar to that of a heating riser. In fact, pouring hot molten metal within 70-80 minutes can produce AZS33WS bricks with a density of over 3.7 g/m³.

Controlling the heat preservation process of the casting to increase the riser feeding distance.

For example, the proper use of feeders and chills can increase the riser feeding distance, thereby reducing the number of risers required. The molten metal entering the mold cavity through the riser inlet preheats the riser molding material, resulting in a higher temperature within the riser and thus reducing the riser’s solidification rate, thereby improving its feeding efficiency.

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!