News detail

What properties of mullite-bauxite castables can be improved by adding cordierite?

Materials containing cordierite not only possess excellent high-temperature resistance but also superior thermal shock resistance. Furthermore, cordierite kiln furniture, cordierite honeycomb ceramics, and applications in high-tech fields such as electronic packaging materials, bioceramics, foam ceramics, printed circuit boards, and low-temperature thermal radiation materials are highly sought after, leading to unprecedented research attention on cordierite materials and making the study of artificially synthesized cordierite a hot topic in the ceramic materials field. Vibratory castables based on mullite and bauxite exhibit strong anti-cracking properties upon initial heating and require low water content. They demonstrate high mechanical strength over a wide temperature range, making them suitable for linings with excellent spalling resistance and wear resistance. Adding cordierite to mullite-bauxite castables can improve their thermal shock resistance.

Experiment

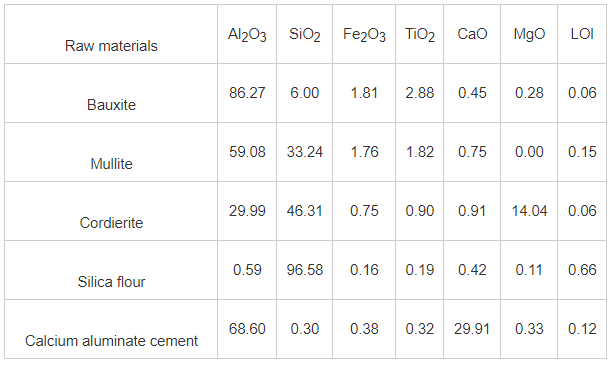

1.Raw Materials and Procedure The main raw materials for this experiment are mullite, bauxite, cordierite, silica fume, and calcium aluminate cement. The main chemical compositions of the raw materials are shown in Table 1.

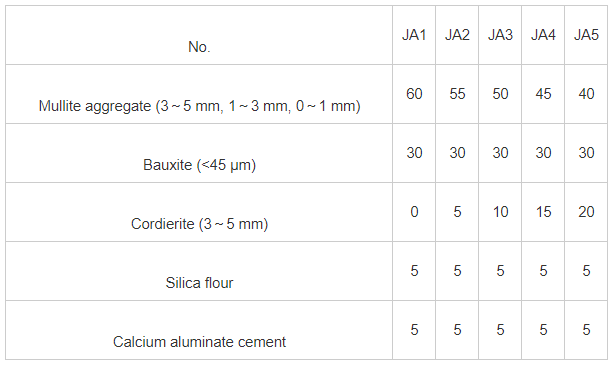

The materials were prepared according to the formula in Table 2. Specifically, the aggregates and powders were added to a mixing tank, stirred evenly, and then water was added and stirred for 3 minutes. Samples of 160mm × 40mm × 40mm were then prepared. After drying at 110℃, the samples were calcined at 1000℃, 1300℃, and 1500℃ for 3 hours, respectively. The bulk density, linear shrinkage rate, flexural strength, and compressive strength of the samples after different heat treatment temperatures were tested. Φ20mm × 100mm samples were prepared to test the coefficient of thermal expansion of the material. 160mm × 40mm × 40mm samples were prepared, dried at 110℃, and then calcined at 1300℃ for 3 hours to test the thermal shock resistance of the material.

2.Performance Testing

The following standards were used: YB/T5200-1993 Test Method for Apparent Porosity and Bulk Density of Dense Refractory Castables; YB/T5203-1993 Test Method for Linear Change Rate of Dense Refractory Castables; and YB/T5201-1993 Test Method for Flexural Strength and Compressive Strength of Dense Refractory Castables at Room Temperature. The bulk density, linear change rate, flexural strength, and compressive strength of the fired samples were tested. The coefficient of thermal expansion of the samples was tested using the GB/T7320.1-2000 Test Method for Thermal Expansion of Refractory Materials – Top Rod Method. The shrinkage of the samples was measured using vernier calipers, and its linear change rate and bulk density were calculated.

Results and Discussion

1.Effects of Cordierite Addition and Heat Treatment Temperature on the Linear Shrinkage Rate of Materials

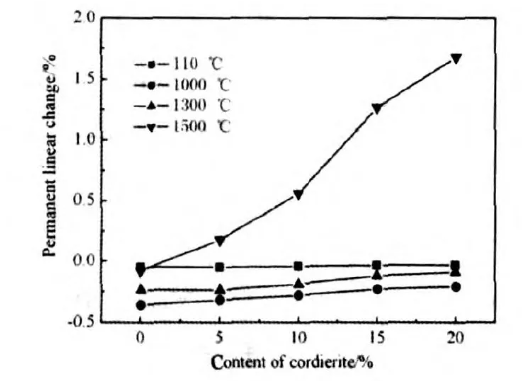

Figure 1 shows the linear shrinkage rates of samples JA1, JA2, JA3, JA4, and JA5 after different heat treatment temperatures with different cordierite content. As can be seen from Figure 1, after drying at 110℃, the linear shrinkage rate of the samples did not change significantly with increasing cordierite content. After heat treatment at 1000℃ and 1300℃, the linear shrinkage rate of the samples gradually decreased with increasing cordierite content. This is because the theoretical composition of cordierite is w(Al₂O₃)=35% and w(SiO₂)=51%, but the cordierite used in this experiment had w(Al₂O₃)=29.99% and w(SiO₂)=46.31%, resulting in an excess of SiO₂. As the cordierite content increases, the amount of free SiO₂ also gradually increases, causing this excess silica to form cristobalite at high temperatures. This transformation is an expansion process, which partially offsets the material’s shrinkage, leading to a gradual decrease in the linear shrinkage rate of the sample as the cordierite content increases.

After heat treatment at 1500℃, the sample gradually changed from shrinkage to expansion as the cordierite content increased, and the expansion rate gradually increased. This is because cordierite melts and decomposes into mullite and magnesia glass at 1435℃, simultaneously expanding. Therefore, after heat treatment at 1500℃, as the cordierite content increases, the sample gradually changes from shrinkage to expansion, and the expansion rate gradually increases. In practical applications, products containing cordierite are typically used at temperatures not exceeding 1400℃. This is because cordierite decomposes above this temperature, causing many of the excellent properties of cordierite-containing materials, such as thermal shock resistance and low coefficient of expansion, to disappear.

After heat treatment at 1500℃, the sample gradually changed from shrinkage to expansion as the cordierite content increased, and the expansion rate gradually increased. This is because cordierite melts and decomposes into mullite and magnesia glass at 1435℃, simultaneously expanding. Therefore, after heat treatment at 1500℃, as the cordierite content increases, the sample gradually changes from shrinkage to expansion, and the expansion rate gradually increases. In practical applications, products containing cordierite are typically used at temperatures not exceeding 1400℃. This is because cordierite decomposes above this temperature, causing many of the excellent properties of cordierite-containing materials, such as thermal shock resistance and low coefficient of expansion, to disappear.

3.Effects of Cordierite Addition and Heat Treatment Temperature on Flexural and Compressive Strength of Materials

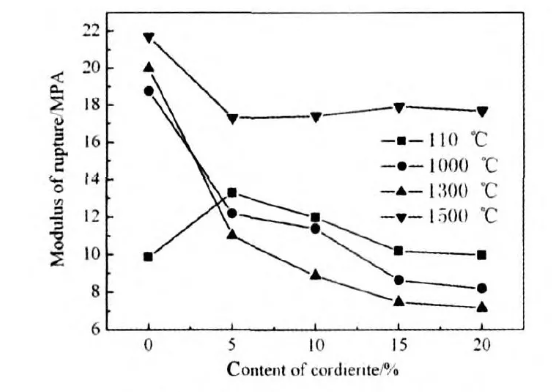

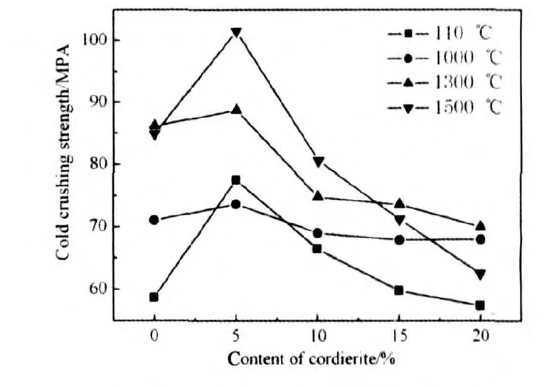

Figures 3 and 4 show the flexural and compressive strengths of samples JA1, JA2, JA3, JA4, and JA5 after different heat treatment temperatures with varying cordierite content. Figures 3 and 4 show that after drying at 110℃, the flexural and compressive strengths exhibit the same trend: they first increase and then decrease with increasing cordierite content, reaching their maximum values when w(cordierite) = 5%. Figure 3 shows that after heat treatment at 1000℃ and 1300℃, the flexural strength of the samples decreases with increasing cordierite content. After heat treatment at 1500℃, the flexural strength of samples with different cordierite contents does not change significantly, but is still lower than that of samples without cordierite. As shown in Figure 4, after heat treatment at 1000℃, 1300℃, and 1500℃, the compressive strength of the samples first increases and then decreases with the increase of cordierite content. Furthermore, when w(cordierite) = 5%, the compressive strength of the samples reaches its maximum value after different heat treatment temperatures. Therefore, when the cordierite content w(cordierite) = 5%, the compressive strength and flexural strength after drying will increase; however, excessive cordierite will decrease the flexural strength and compressive strength of the material after different heat treatment temperatures.

4.Effect of Cordierite Addition on the Coefficient of Thermal Expansion of the Material

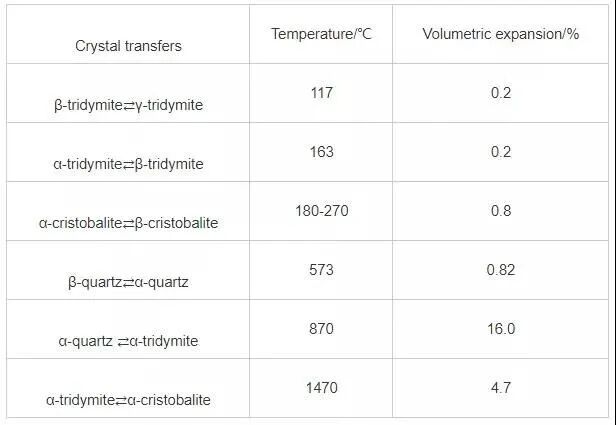

With the increase of cordierite content, the coefficient of thermal expansion of the sample increased slightly. Theoretically, the introduction of cordierite should reduce the coefficient of thermal expansion of the material. However, as mentioned earlier, the chemical composition of the cordierite used in this experiment differs somewhat from the theoretical value, resulting in an excess of silica. This leads to a series of quartz crystal transformations during heating, causing volume expansion (see Table 3), thus correspondingly increasing the coefficient of thermal expansion of the material. It can also be seen that the coefficients of thermal expansion of samples JA3 and JA5 with cordierite additions of w(cordierite) = 10% and w(cordierite) = 20% are not significantly different.

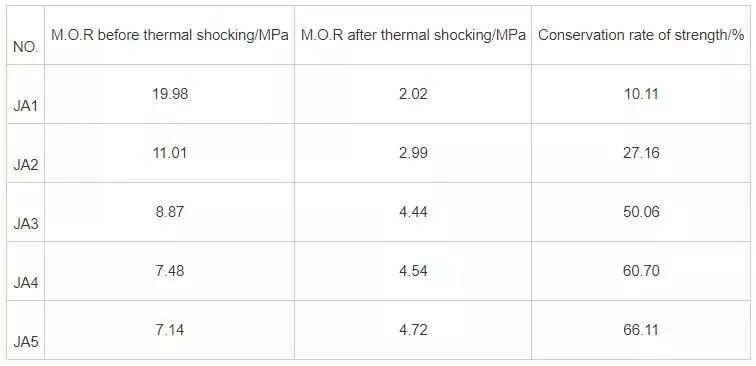

5.Effect of Cordierite Addition on Thermal Shock Resistance of Materials

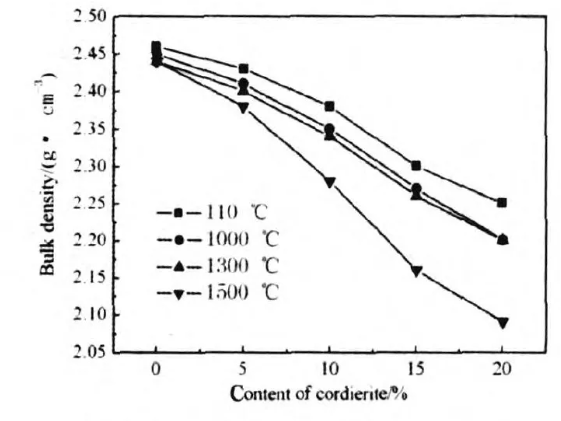

Table 4 shows the comparison of flexural strength of sintered samples before and after thermal shock. Table 4 shows that the strength retention rate of the material gradually increases with the increase of cordierite content. Figure 2 shows that the bulk density of the samples decreases regularly with the increase of cordierite content, indicating a gradual increase in porosity. Although excessive porosity has an adverse effect on the strength of the material, it is precisely because of the high porosity that the material has good resistance to thermal shock damage, thus achieving a high strength retention rate with increasing porosity. Furthermore, as shown in Figure 5, the addition of cordierite did not reduce the coefficient of thermal expansion of the material, and even slightly increased it. However, because the introduction of cordierite reduced the bulk density and increased the porosity, its thermal shock resistance was compensated. Therefore, adding cordierite to mullite-bauxite castables still results in a material with excellent thermal shock resistance.

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!