News detail

Semi-lightweight mullite castable for tundish lining

Heat loss in molten steel within the tundish mainly occurs in three forms: heat dissipation from the upper surface of the tundish, heat storage within the lining, and heat conduction to the outer shell through the lining. By optimizing the performance indicators of the tundish lining castable, a long-life semi-lightweight mullite castable is developed to achieve safe, stable, long-life, and energy-efficient operation of the tundish.

Semi-lightweight mullite castable performance characteristics

The suitable Al₂O₃ content in the permanent lining castable ensures good slag resistance and thermal shock resistance. The raw material has a low iron oxide content, and the high-valence iron and low-valence iron exhibit a significant volume expansion effect during temperature drop. Therefore, the level of iron oxide content and the uniformity of impurity distribution both affect the material’s thermal shock resistance. Only a low thermal conductivity in semi-lightweight castables can ensure good overall insulation performance. The permanent lining of the tundish uses castables with an Al₂O₃ content of 60%~65%, whose main phase is mullite, exhibiting good thermal shock resistance.

Semi-lightweight mullite raw material

Two types of mullite raw materials with different particle sizes were used in the tundish permanent lining castable. Their appearance is shown in Figure 1(a, b). As can be seen from the figure, the mullite particles are pale yellow, with distinct edges and corners, and most particles are flaky.

1.Physical Properties

The physical properties of the mullite particles shown in Figure 1 are listed in Table 1. As can be seen from the table, the apparent porosity of 5–3 mm particles is slightly lower than that of 8–5 mm particles, while their bulk density is slightly higher. This is related to the fact that smaller particles typically fracture along larger pores, thus eliminating some defects.

2.Chemical Analysis

Table 2 shows the chemical analysis of the two particle size light mullite raw materials and their main components. As can be seen from the table, the chemical composition of the two particle size raw materials is basically the same, with Al₂O₃ and SiO₂ as the main components. TiO₂ is introduced from the natural raw material bauxite. The total content of other impurities is low, and R₂O content is 0.08%.

Regarding slag resistance, for Al₂O₃-SiO₂ series raw materials, the higher the Al₂O₃ content, the greater the expansion and the worse the thermal shock resistance; for sintered mullite, the lower the iron content, the better the thermal shock resistance. Therefore, to ensure good thermal shock resistance, the Al₂O₃ content in the castable needs to be controlled and should not exceed 65%.

3.Phase Analysis

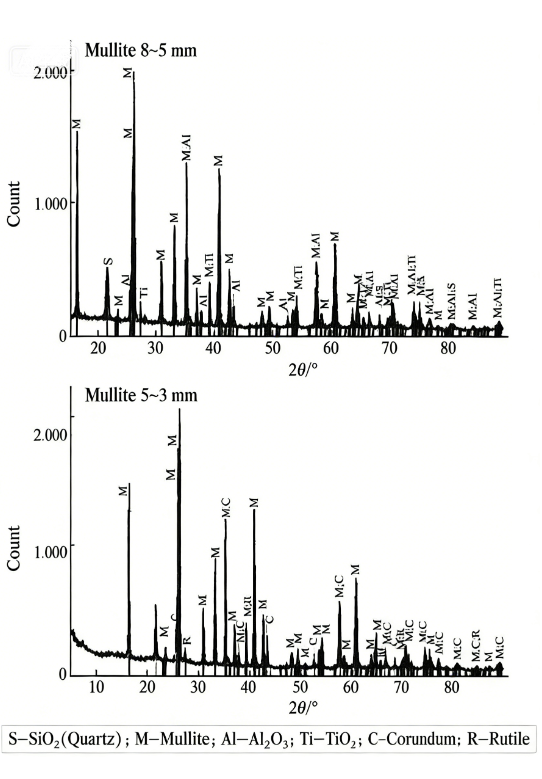

Figure 2 shows the XRD analysis of the mullite raw material.

As shown in Figure 2, the phase composition of the two types of mullite particles is basically the same, with the main phases being mullite, corundum and quartz, and a small amount of TiO₂.

4.Microstructure Analysis

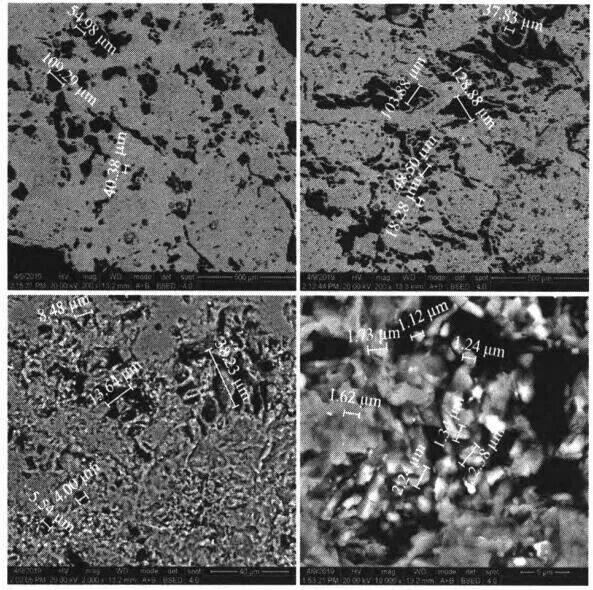

The microstructure of the mullite raw material is shown in Figure 3. As can be seen from Figure 3, the semi-lightweight mullite contains numerous irregularly shaped pores ranging from 20 to 60 μm, and a large number of closed pores ranging from 1 to 10 μm within the grains. The mullite single crystal size is 1 to 3 μm, and it is granular.

Field application test of semi-lightweight mullite castable

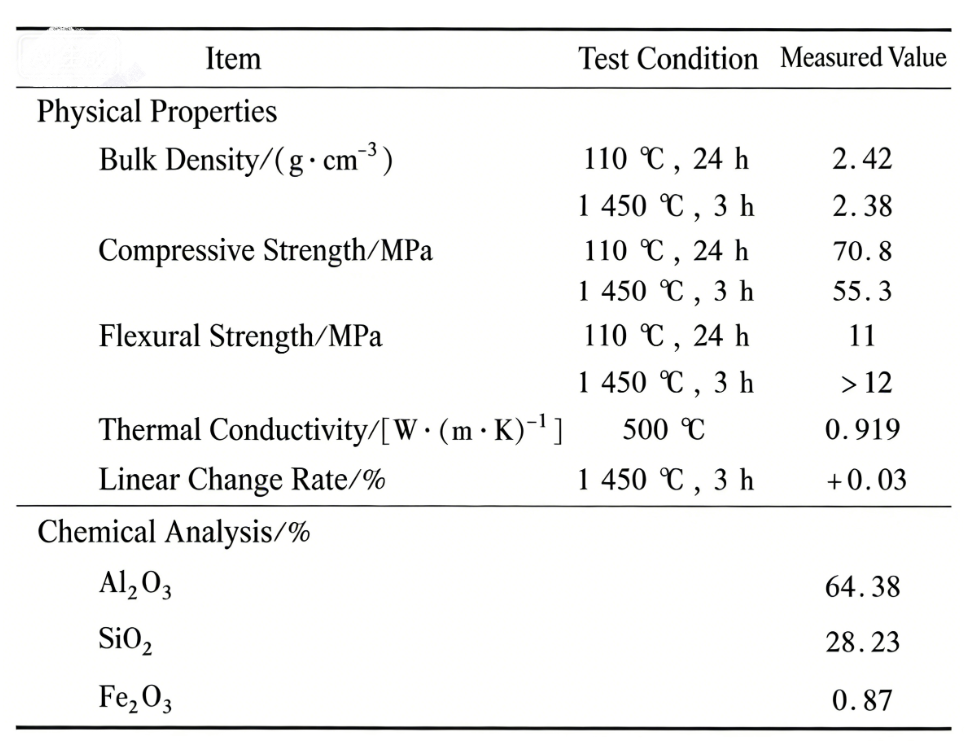

The permanent lining of the tundish used semi-lightweight mullite castable showed good performance during use. Table 3 lists the measured performance indicators of this type of castable

3.1 Results of Tundish Thermal Balance Simulation Calculation

The safety of various materials used in the tundish was assessed by calculating the interface temperatures through thermal balance simulation. The simulation parameters were set as follows: steel plate thickness 30mm, insulation board 5mm, lightweight brick 30mm, castable refractory 185mm, coating thickness 40mm, and the interface temperature between the working lining and molten steel 1550℃. After reaching thermal balance, the simulation results showed the following interface temperatures: coating and castable refractory interface temperature 1430℃; castable refractory and lightweight brick interface temperature 956℃; lightweight brick and insulation board interface temperature 737℃; and insulation board and steel shell interface temperature 202℃.

The simulation results indicate that all materials are within safe operating ranges. Heat transfer simulation calculations were performed on the brick-built tundish and the test tundish (using semi-lightweight mullite castable) after reaching thermal equilibrium. The results showed that the steel shell temperature of the brick-built tundish after reaching thermal equilibrium was 298.2℃, and the heat loss through the steel shell of the tundish was 6749.8W/m²; the steel shell temperature of the test tundish after reaching thermal equilibrium was 201.6℃, and the heat loss through the steel shell of the tundish was 3237.5W/m².

3.2 Evaluation of Tundish Insulation Effect

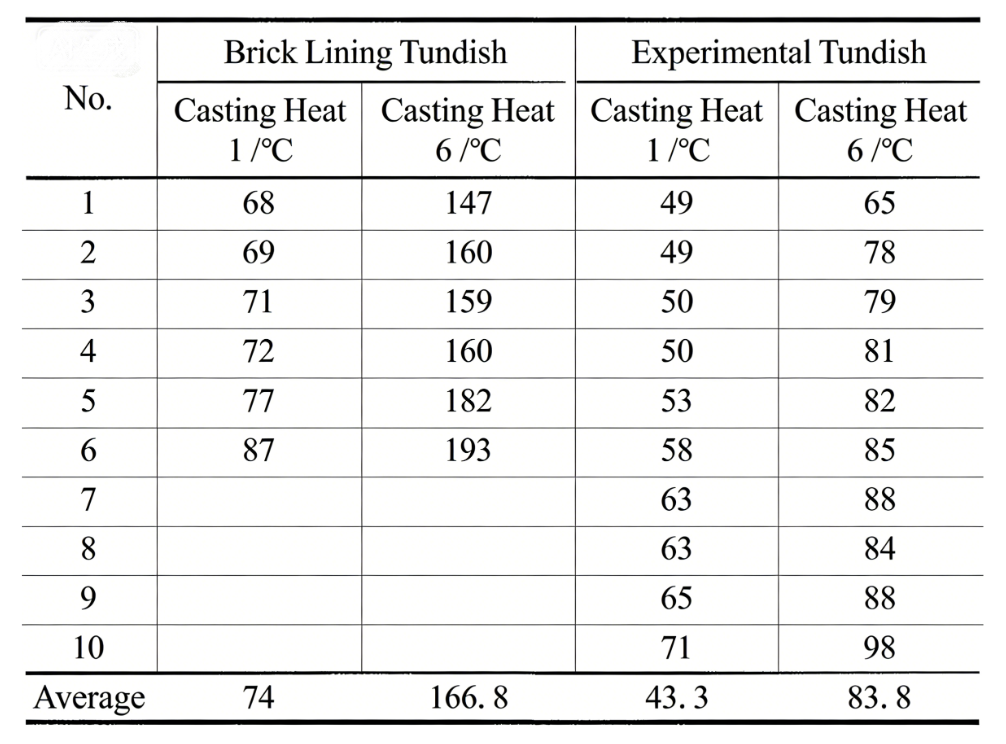

The temperature of the tundish steel shell was measured, and the results are listed in Table 4.

As shown in Table 4, compared with brick-built tundishes, the test tundish with heat-insulating lining and mullite castable permanent lining exhibits significantly lower steel shell temperatures in the later stages of the same casting cycle, demonstrating a clear heat insulation effect and reduced heat loss. Based on six casting cycles, the test tundish, compared with brick-built tundishes, showed a decrease in average steel shell temperatures of 17℃ and 83℃ for the first and sixth casting cycles, respectively. Furthermore, the temperature drop in the test tundish became more pronounced with increasing number of consecutive casting cycles.

Conclusions

(1) Using semi-lightweight mullite castable for the tundish lining ensures good slag resistance, thermal shock resistance, and low thermal conductivity, thereby improving the tundish’s service life.

(2) Compared with brick-built tundishes, tundishes using semi-lightweight mullite castable have less heat loss and significant thermal insulation effects, which is beneficial for stabilizing steel temperature during casting and thus improving billet quality.

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!