Product detail

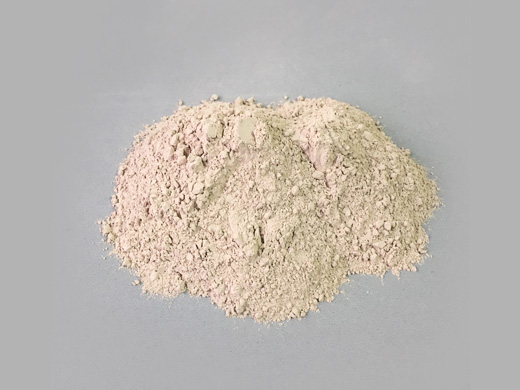

Silica Ramming Mass

Main Composition:SiO2

Application:Smelting bronze

Capacity:3000 tons per month

Raw Material:Quartz sand

Package:Export ton bag

Product Introduction

Silica ramming mass is made by mixing high-purity microcrystalline quartz sand, powder, high-temperature sintering agent and mineralizer. The silica ramming mass has a short oven time, has good volume stability, thermal shock stability and high high temperature strength.

Features

1.Good stability.

2.Good slag resistance.

3.Good fire resistance and resistance to melt erosion.

4.Good chemical stability.

Application

It is mainly used for smelting bronze and red copper in industrial frequency furnace and intermediate frequency furnace.

Product Parameters

| Item | CN-1 | CN-2 | CN-3 | CN-4 | CN-5 | |

| Chemical composition(%) | SiO2>= | 95 | 96 | 96 | 97 | 90 |

| Al2O3<= | 0.7 | 0.6 | 0.6 | 0.5 | 0.4 | |

| Fe2O3<= | 0.5 | 0.5 | 0.4 | 0.4 | 0.8 | |

| Cold crushing strength(Mpa) | 1300℃×3hAfter firing at | 15 | 15 | 10 | 10 | 25 |

| Apparent porosity (%) | 1300℃×3hAfter firing at | 26 | 26 | 25 | 25 | 23 |

| Linear changing after burnt(%) | 1300℃×3hAfter firing at | 0~+1.6 | 0~+1.2 | 0~+1.0 | ||

| Bulk density (g/cm3) | 1300℃×3hAfter firing at | 2.0 | 2.0 | 2.1 | 2.1 | 2.2 |

| Refractoriness(℃) | 1630 | 1650 | 1650 | 1680 | — | |

| Max. grain size of aggregate(mm) | 5 | 4.5 | 4.5 | 4.2 | 4.2 | |

| Amount for construction(kg/m3) | 2300 | 2300 | 2300 | 2400 | 2400 | |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!