Product detail

Fireclay bricks for Hot Blast Stove

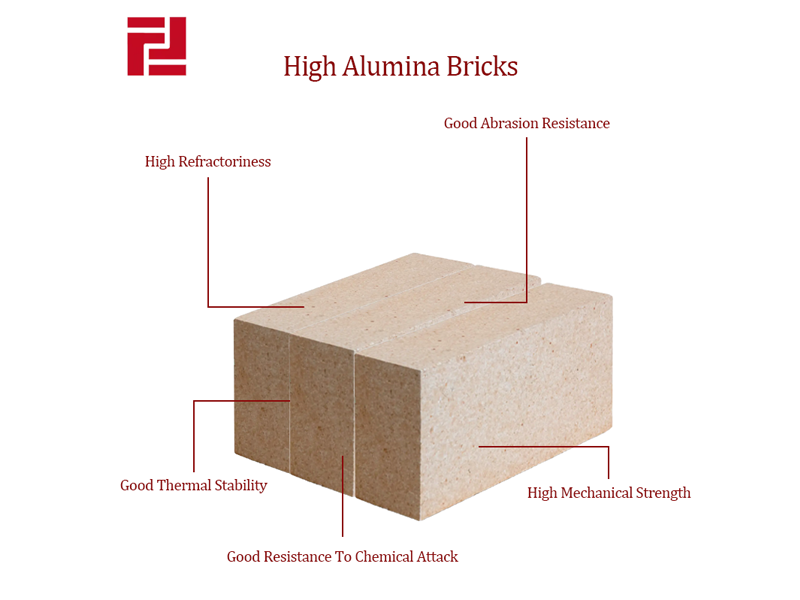

Fireclay bricks for hot blast stoves are clay bricks made from refractory clay and used to build blast furnace hot blast stoves. Fireclay bricks for hot blast stoves are used for hot blast stoves, regenerators and partition walls. Fireclay bricks for hot blast stoves require good thermal shock resistance, high load softening temperature and low creep.

Composition & Manufacturing

- Raw materials: Refractory clays (kaolin-based), clay grog as aggregate, and plastic clay binders. Typically Al₂O₃ 35–45%, SiO₂ as the main matrix, forming mullite crystals during firing; classified as weakly acidic refractories.

- Process: Crushing → batching → high-pressure molding → drying → sintering at ~1350–1450°C. Low-creep grades may add andalusite/mullite to optimize microstructure.

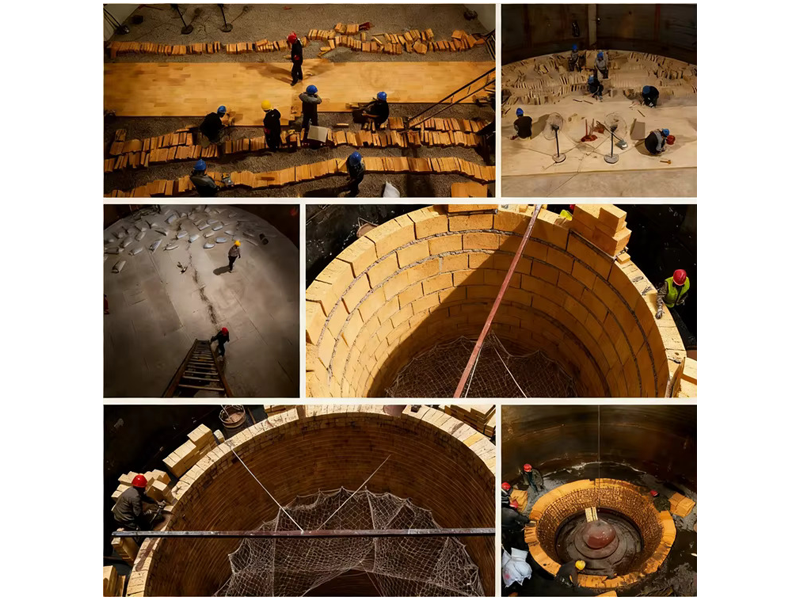

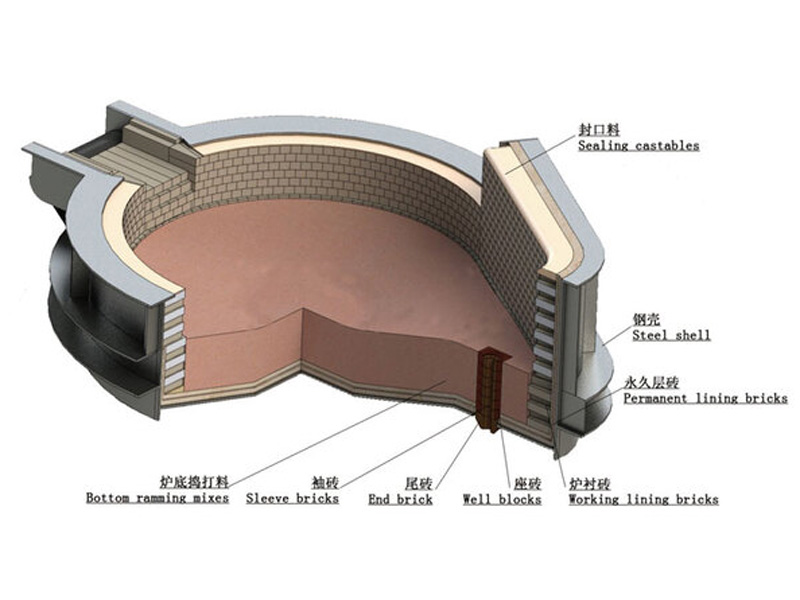

Applications in Hot Blast Stoves

- Regenerator checker bricks: The most common use, shaped into honeycomb/plum-blossom patterns to maximize heat storage/exchange area.

- Wall & partition bricks: For the middle/lower sections of the stove body.

- Arch bricks: For the vault area with combined thermal and mechanical stress.

- Not recommended for the extreme-temperature combustion chamber; usually replaced by high-alumina or silica bricks there.

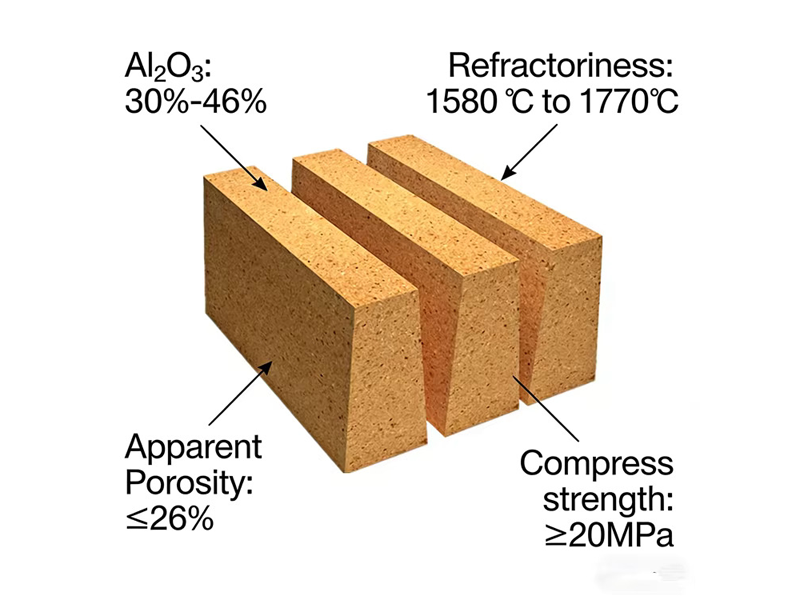

Product Parameters

| Item 项目 |

Fireclay bricks for Hot Blast Stove 热风炉用粘土砖 |

|||

| RN-42 | RN-40 | RN-36 | ||

| Al2O3(%) | ≥ | 42 | 40 | 36 |

| Apparent Porosity 显气孔率(%) |

≤ | 24 | 24 | 26 |

| Refractoriness 耐火度(℃) |

≥ | 1750 | 1730 | 1690 |

| Cold Crushing Strength 常温耐压强度(Mpa) |

≥ | 29.4 | 24.5 | 19.6 |

| Refractoriness under Load 荷重软化开始温度(℃) (0.2Mpa) |

≥ | 1400 | 1350 | 1300 |

| Reheating Linear Change Rate 重烧线变化(%) |

1400℃×2h | 0~0.4 | ____ | ____ |

| 1350℃×2h | ____ | 0~0.3 | 0~0.5 | |

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!