Product detail

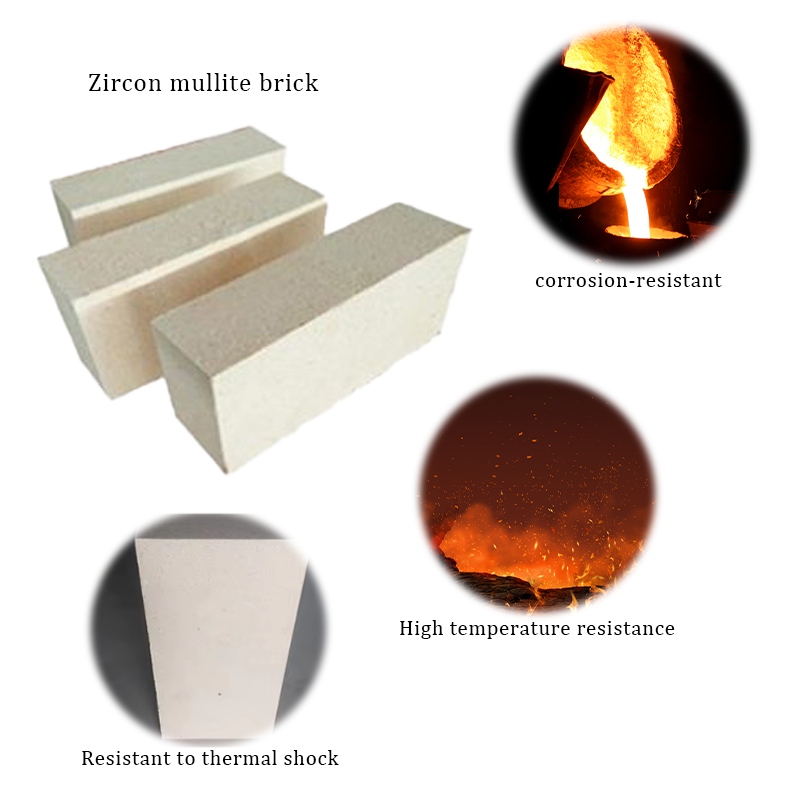

zirconium mullite bricks for glass furnaces

Sintered zirconium-mullite bricks are specialty refractory materials made from industrial alumina and zircon concentrate. Zirconia is incorporated into a mullite matrix through a reaction sintering process. The introduction of zirconium oxide into mullite bricks significantly improves the high-temperature mechanical properties of the mullite material by utilizing its phase transformation toughening effect. Zirconia also promotes the sintering of mullite. The addition of ZrO2 accelerates the densification and sintering of ZTM materials by generating low-melting-point species and creating vacancies.

Product Features:

1. Resistant to molten glass and alkali corrosion, highly resistant to erosion.

2. High mechanical strength and good thermal shock resistance.

3. Low thermal shrinkage and high-temperature creep.

4. Dense crystal structure.

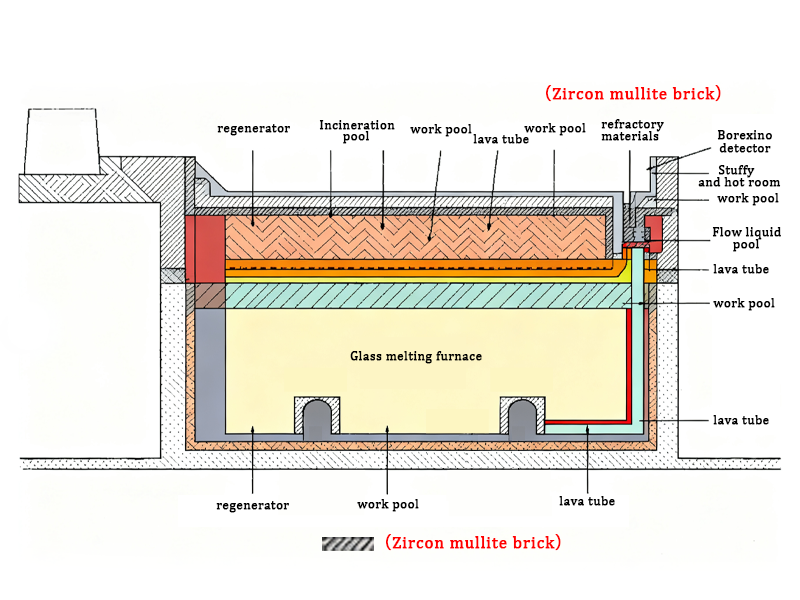

It is primarily used for glass melting and cooling floor masonry, small kilns, regenerator grids, and L-shaped wall noses. It is an indispensable key support material for large float glass kilns. It is also used for large glass kiln melting tanks, cathode ray tube kilns, regenerator partitions, and chemical and metallurgical kilns subject to solution corrosion.

Product Parameters

| Item | Zircon mullite brick | ||

| Trademark | ZM-20 | ZM-16 | ZM-12 |

| ZrO2(%) | ≥20 | ≥16 | ≥12 |

| SiO2(%) | / | / | / |

| Fe₂O3(%) | ≤0.3 | ≤0.3 | ≤0.3 |

| Bulk Density(g/cm3) | ≥3.00 | ≥2.9 | ≥2.9 |

| Apparent Porosity(%) | ≤10 | ≤11 | ≤11 |

| Cold Crushing Strength(Mpa) | ≥100 | ≥100 | ≥100 |

| Refractoriness under Load(0.2Mpa,0.6%) | ≥1700 | ≥1700 | ≥1700 |

| Thermal shock stability(1100℃×24h) | Excellent | ||

| 1400℃×50h creep rate | Excellent | ||

| Typical Application | This series of products has good resistance to alkali steam and thermal shock. It is mainly used in the flame space of glass furnaces and can also be used in float glass furnaces. ZM-16 is used for pure oxygen burning burner bricks in alkali-free glass melting kilns,domes of ceramic frit glaze kilns,loud bricks and other parts of industrial kilns with high temperature and large thermal stress. | ||

Send inquiry

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!